|

Brian's Guitar from Conception to Birth

or How to Build a Guitar in 62 Easy Steps! |

|

53

Rub Out the Finish |

Remember to wait a week after spraying the last coat before you

touch the guitar. If you did all of your preparation, sanding, and

spraying carefully, you should see a pretty smooth surface. But itís

not smooth enough! As they stay in all of the books Iíve read (and

itís clever enough to repeat here), itís time to finish the finish.

|

|

|

|

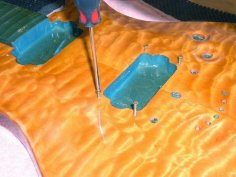

From now on, always rest your guitar on a clean, soft towel when

working on it so it doesnít get scratched. Start off by removing the

screws protecting the mounting holes and take all of the tape off

the guitar. The lacquer will have built up over the top of the tape

and you want to be sure the sanding youíll be doing will ease the

edges of the lacquer to bare wood abutments. Also, even though you

used the easy-release painterís tape, after being on for about a

month, it will have begun to stick and leave some residual goo

behind. Use an Exacto blade, but do NOT cut with it which might

gouge the wood. Instead, scrape backwards with the blade at the

corners of the cavities. This will shave the edge of the lacquer off

so when you peel off the tape, you donít peel the lacquer off with

it. Use the point of the knife or a dental pick to thoroughly clean

off all of the tape which might be hiding in the corners. Inspect

for any sticky glue stuff remaining on the bare wood and clean it

off with some mineral spirits.

They call it rubbing even though it is actually sanding. The high

grit sandpapers donít produce much visible dust, so I guess they

thought rubbing was a better term. When rubbing out the finish with

these fine grit sandpapers, you need some kind of lubricant. It

makes the rubbing a bit easier, it extends the life of your sand

papers, and it helps carry off the fine dust. In an old spray

bottle, mix up one part mineral spirits with one part paraffin oil

(about 8 ounces of each should be enough for the whole job).

Use

a foam or felt sanding block as much as possible and for all grits

which helps keep the surface level and eases hand fatigue. I like to

start with 600 grit wet/dry sandpaper before moving into the

MicroMesh abrasives. Now donít go hosing down the piece with the

lubricant; youíll end up with oil all over the place. Just spray

once in the middle of the guitar and a little here and there, or

when rubbing a smaller area or and edge, spray a small amount

directly on the paper. Sand with firm pressure. Start by rubbing the

whole surface in small circles, then rub 45 degrees to the grain

direction, then rub with the grain direction. Now repeat this to

yourself over and over again: ďDo not skimp on the sanding.Ē If you

get lazy on only one grit, it wonít become evident until you get to

the last grit and itís not as glossy as it should be. This is why I

recommend rubbing in three different fashions, so youíre sure to rub

everything thoroughly. With these finer grits, itís impossible to

sand too much. Donít worry, there is no danger of sanding through 30

coats of lacquer. Use

a foam or felt sanding block as much as possible and for all grits

which helps keep the surface level and eases hand fatigue. I like to

start with 600 grit wet/dry sandpaper before moving into the

MicroMesh abrasives. Now donít go hosing down the piece with the

lubricant; youíll end up with oil all over the place. Just spray

once in the middle of the guitar and a little here and there, or

when rubbing a smaller area or and edge, spray a small amount

directly on the paper. Sand with firm pressure. Start by rubbing the

whole surface in small circles, then rub 45 degrees to the grain

direction, then rub with the grain direction. Now repeat this to

yourself over and over again: ďDo not skimp on the sanding.Ē If you

get lazy on only one grit, it wonít become evident until you get to

the last grit and itís not as glossy as it should be. This is why I

recommend rubbing in three different fashions, so youíre sure to rub

everything thoroughly. With these finer grits, itís impossible to

sand too much. Donít worry, there is no danger of sanding through 30

coats of lacquer.

|

|

|

|

The 600 grit is the most important since this will perform the

leveling; you will not be able to level the surface with the

MicroMesh abrasives. Start with the back of the guitar, spray on

some lubricant, and rub thoroughly as noted above. When youíre done

with the back, wipe it down with mineral spirits to remove any dust.

Now inspect the surface very carefully in a low-angle, grazing

light. Youíll first notice that your beautiful shiny guitar is

suddenly dull. Everythingís alright, thatís whatís supposed to

happen. Youíll get it brilliant looking again after working through

all of the grits. What youíre looking for are any shiny spots or any

unevenness in the surface. The shiny spots will show the low areas

which did not get sanded with the block. If the surface is not dead

flat, sand more with the 600 grit until it is. If the surface is

really off, you may have to take a step back to 400 grit for a more

aggressive attack, then back up to 600 grit again to start

smoothing. Take extra time on the first grit until the surface is

perfectly level with no dimples. Only then can you continue to the

finer MicroMesh abrasives.

There are 9 grits of MicroMesh abrasives, and at about 20 minutes

per grit, this will take you a while. Find your rhythm and rub all

surfaces in the same order so you donít forget an area. I did the

body back first, then the headstock, cavity cover, truss rod cover,

body front, then finally the body sides. Add a spritz of lubricant

as needed. When you finish an area, wipe it off with mineral spirits

and inspect. When you finish a grit, take a short break, then repeat

the procedure with the next grit. You can split the rub out over a

couple-three days so you donít get too tired or bored with it. |