|

|

Beauty is in the details. Click

on the photos to see them in a larger size. Use your browser's

"Back" button to return. |

|

|

|

December 11, 2008 |

Welcome, Jeff!

I purchased the first few pieces of wood for your jewelry box today.

I know we didn't talk much about the design details and cost and

such, but even if you decide (for whatever reason) that the piece

isn't right for you, it is absolutely no problem whatsoever. I

will be building a total of five jewelry boxes at the same time so

I'll have something to sell on the web site. I have one box

spoken for already, but you will have your choice from the remaining

four.

The

basic design is shown in the image to the right (you can always

click on these pictures to see a larger image). It is art deco

styling made from contrasting woods. There's tiger maple for

the front/top/back and a darker wood for the sides/legs/arches

(either mahogany, cherry, or walnut). The top can be done in a

stained glass design or monogram. You could simply choose some

fancy wood for the top, but the interior of the box will be lit with

small LED lights! When turned on, it will cast a beautiful

glow through the glass. The decorative element on the front

will serve as a lift-handle and a drawer pull. The overall

size is generous at about 21"w x 18"d x 9"h. It will hold two

of the 12"x15" jewelry trays shown below. Your wife may have

more jewelry than that, but we can probably agree that I could never

make a box large enough to house her entire collection. This

will certainly serve as a focal point in the room. The

basic design is shown in the image to the right (you can always

click on these pictures to see a larger image). It is art deco

styling made from contrasting woods. There's tiger maple for

the front/top/back and a darker wood for the sides/legs/arches

(either mahogany, cherry, or walnut). The top can be done in a

stained glass design or monogram. You could simply choose some

fancy wood for the top, but the interior of the box will be lit with

small LED lights! When turned on, it will cast a beautiful

glow through the glass. The decorative element on the front

will serve as a lift-handle and a drawer pull. The overall

size is generous at about 21"w x 18"d x 9"h. It will hold two

of the 12"x15" jewelry trays shown below. Your wife may have

more jewelry than that, but we can probably agree that I could never

make a box large enough to house her entire collection. This

will certainly serve as a focal point in the room.

I will try to post some updates here about once a week. I

still have a day job plus I'm making five of these boxes at a time,

so progress will be at a slow but steady pace. I'm projecting

completion near the end of March. Feel free to stop by any

time to look at the progress in person and see which box you might

be interested in. If anyone else you know might be interested in some custom

woodwork, I'd appreciate a referral. Thanks. |

|

|

|

December 27, 2008 |

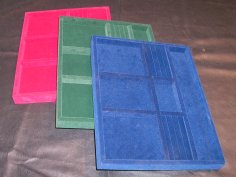

I ordered the jewelry trays today. I didn't know what color

you would want so I just bought some in each color they had.

What I don't use in your box will go in one of the other boxes I'm

making. I usually don't like buying pre-manufactured items

like this, but these are very high quality and I'm not sure I could

make them for the same cost. I also picked up the hinges. They're solid

brass, of course, with a stop which will hold the lid open at 95

degrees. I ordered the jewelry trays today. I didn't know what color

you would want so I just bought some in each color they had.

What I don't use in your box will go in one of the other boxes I'm

making. I usually don't like buying pre-manufactured items

like this, but these are very high quality and I'm not sure I could

make them for the same cost. I also picked up the hinges. They're solid

brass, of course, with a stop which will hold the lid open at 95

degrees. |

|

|

|

January 4, 2009 |

|

Last week, I dimensioned the lumber for the legs and sides.

It looks like I'm going to be a little short on wood, so I'll have to get more to finish

all the boxes I'm making in this series. |

|

|

|

January 11, 2009 |

I dimensioned and cut all the drawer parts, the sides and bottoms.

I cut all the joinery on the drawer corners. The first photo

shows an assembled drawer with the drawer slide attached. I

like to use high quality, ball bearing slides. They add a

little cost, but the drawers will work super-smooth. I'm using

"over-extension" slides which allow the drawer to be pulled out all

the way giving easy access to the back of the drawer. I also

used the box-jointed corners which are incredibly strong. I dimensioned and cut all the drawer parts, the sides and bottoms.

I cut all the joinery on the drawer corners. The first photo

shows an assembled drawer with the drawer slide attached. I

like to use high quality, ball bearing slides. They add a

little cost, but the drawers will work super-smooth. I'm using

"over-extension" slides which allow the drawer to be pulled out all

the way giving easy access to the back of the drawer. I also

used the box-jointed corners which are incredibly strong. |

|

|

|

January 18, 2009 |

|

I glued up the drawers and sanded them smooth. The sides,

legs, and arches were rough-cut. I also dadoed the side panels

to accept the case fronts and backs. You might have to click

on the photo (below) to catch some of the details, but there are

shallow grooves (dados) running horizontally which will house the

case/compartment bottoms. There's a vertical groove to the

left which will nest the back panel of the box. The right side

has notches cut out to receive the case front pieces. This

interlocking joinery takes time, but will provide a much more solid

assembly. I inlayed a thin strip of complimentary wood across

the top which will provide a little visual interest when you open

the box. It is easiest to install the drawer slides before

assembly since it would be difficult to get a screw gun inside the

box after it's put together. |

|

|

|

January 25, 2009 |

I cut all the pieces for the front and back panels, drawer fronts,

and lids to size. I added the inlay decoration on the side

panels. These inlays have different woods and patterns for

each box in this series. This photo shows a quilted maple

inlay in a wenge wood side panel. I enjoy these spontaneous

embellishment. I had a little fancy wood leftover and this

seemed like a good place to put it. This wenge wood/ tiger

maple box is the one which is already spoken for. All the

boxes will have tiger maple fronts, but there will also be mahogany,

cherry, and walnut side panels from which to choose. I cut all the pieces for the front and back panels, drawer fronts,

and lids to size. I added the inlay decoration on the side

panels. These inlays have different woods and patterns for

each box in this series. This photo shows a quilted maple

inlay in a wenge wood side panel. I enjoy these spontaneous

embellishment. I had a little fancy wood leftover and this

seemed like a good place to put it. This wenge wood/ tiger

maple box is the one which is already spoken for. All the

boxes will have tiger maple fronts, but there will also be mahogany,

cherry, and walnut side panels from which to choose.

|

|

|

|

February 1, 2009 |

I cut in all the dadoes

in the side panels to nest the front and back panels. All

of the drawer hardware was pre-installed (see photo in previous

entry). The bottom panels

were dadoed to receive the back panels. Again, with many parts

interlocking, the box will be very strong. The legs were cut to

size and then shaped. The far right photo shows the wenge wood

sides with a couple of legs to the left. You can also see the

bevy of other case parts in the background. Sometimes it can

be a little difficult to keep all these pieces in order. I cut in all the dadoes

in the side panels to nest the front and back panels. All

of the drawer hardware was pre-installed (see photo in previous

entry). The bottom panels

were dadoed to receive the back panels. Again, with many parts

interlocking, the box will be very strong. The legs were cut to

size and then shaped. The far right photo shows the wenge wood

sides with a couple of legs to the left. You can also see the

bevy of other case parts in the background. Sometimes it can

be a little difficult to keep all these pieces in order.

|

I

rough-cut all of the interior partitions and dividers which will

serve as the small wiring raceways for the LED lights. These

are all the stacks of wood for each box. The right photo is a

shot of all the leg and arch pieces ready for final shaping and

installation. I

rough-cut all of the interior partitions and dividers which will

serve as the small wiring raceways for the LED lights. These

are all the stacks of wood for each box. The right photo is a

shot of all the leg and arch pieces ready for final shaping and

installation. |

|

|

|

February 8, 2009 |

|

|

|

|

I began assembly on the first box in this series. All of the

pieces are fine-tuned for a perfect, tight fit. I installed

the drawer fronts. Notice how the ball bearing slides allow

the drawer to extend all the way out allowing complete access. I also rough-cut the

lift handle and drawer pull assemblies. This will create a

functional and aesthetic embellishment for the front of the box.

Once again, I'm guilty of creating a bunch of small pieces which I'll

need to label and track. |

|

|

|

February 15, 2009 |

|

|

|

|

I glued up the lid segments, basically the front face of the lid to

the top frame of the lid. The leftmost photo shows the twenty

segments for all five boxes in this series; your box will only use

four of these segments.

I also added a wood inlay at the abutment of those two pieces.

This provides additional strength to the joint and it looks cool.

I cut out the drawer pull and lift handle pieces. The lower

portion of the circle design will be mounted to the drawer and has a

finger-pull routed into the bottom of it (you can just see it in the

photo). The top portion will be mounted to the lid so you grab

it to lift it. The two side pieces are decorative and will

complete the circular design. |

|

|

|

February 22, 2009 |

|

|

|

|

All of the lid segments which were produced last week had their

corners mitered and their assemblies glued up. Now that all of

the lids are together, it's possible to take the precise

measurements needed for the stained glass inserts which will

eventually call those lids home. So very soon

you will need to make your final decision on the glass design and

color scheme. We'll need to get together so you can see some

glass samples or I can shop with you for glass and make

recommendations if you'd like. The rightmost photo above shows

a detail of a lid's corner. There's a wood band inlayed on top

which will frame the stained glass and two corner "keys" on the side

which are decorative and add strength to the corner joint.

These are in the same wood of which the box sides are made to tie

the design and color scheme together. |

|

|

|

March 2, 2009 |

All

of the boxes were assembled. The hinges were mortised

(recessed) and the lids were installed and tuned for smooth

operation. I began installing the front lift handle and drawer

pull assemblies. Things are really beginning to take shape

now. All

of the boxes were assembled. The hinges were mortised

(recessed) and the lids were installed and tuned for smooth

operation. I began installing the front lift handle and drawer

pull assemblies. Things are really beginning to take shape

now. |

|

|

|

March 8, 2009 |

I

had to completely assemble the jewelry boxes so that everything

could be cut to exact size and all the hardware could be installed.

However, there is no way I could apply finish to the interior

portions of the box while it's assembled; I can't even fit my hand

into the drawer cavity. So your box was completely

disassembled (into about 30 pieces) and everything was sanded

smooth. I could then apply the oil and spray on the lacquer

much more easily. Your stained glass panel was also completed;

it looks fantastic! Stop by and check it out if your get a

minute. I

had to completely assemble the jewelry boxes so that everything

could be cut to exact size and all the hardware could be installed.

However, there is no way I could apply finish to the interior

portions of the box while it's assembled; I can't even fit my hand

into the drawer cavity. So your box was completely

disassembled (into about 30 pieces) and everything was sanded

smooth. I could then apply the oil and spray on the lacquer

much more easily. Your stained glass panel was also completed;

it looks fantastic! Stop by and check it out if your get a

minute. |

|

|

|

March 16, 2009 |

After

the glass pieces are assembled and all the joints are soldered, a

special cement is forced under the lead to hold the glass secure.

The white powder you see helps the cement cure. This method of

concealment in the photo also helps build your anticipation.

Yours is the right panel (upside down); the other panel is for

another client. After

the glass pieces are assembled and all the joints are soldered, a

special cement is forced under the lead to hold the glass secure.

The white powder you see helps the cement cure. This method of

concealment in the photo also helps build your anticipation.

Yours is the right panel (upside down); the other panel is for

another client.

I also assembled all the pieces which were sprayed with lacquer last

week. The legs and top arches were added, the outside

completely sanded, and a coat of linseed oil was applied to bring

out the color and grain. This will ultimately be a three-toned

piece. The tiger maple front will remain light, the mahogany

legs and top arches will stay a medium tone, and the cherry side

panels will darken a bit more over time. It will be

spectacular! We're in the home stretch now. |

|

|

|

March 23, 2009 |

I

sprayed the final coats of lacquer on your jewelry box (yours is the

brownish-colored one in front). There's a total of 6 coats of

lacquer on there which will give it a very nice, glossy sheen.

The last time you saw the boxes they were without any finish.

I think you'll be pleasantly surprised when you see how much the

wood grain and color comes out when you oil and lacquer it.

The tiger maple on the front of your box is absolutely striking. I

sprayed the final coats of lacquer on your jewelry box (yours is the

brownish-colored one in front). There's a total of 6 coats of

lacquer on there which will give it a very nice, glossy sheen.

The last time you saw the boxes they were without any finish.

I think you'll be pleasantly surprised when you see how much the

wood grain and color comes out when you oil and lacquer it.

The tiger maple on the front of your box is absolutely striking. |

|

|

|

March 30, 2009 |

Finished

and ready for delivery! I think you'll find the results

spectacular. The combination of different woods creates a

wonderful contrast. The texture of the tiger maple is three

dimensional, almost holographic. The stained glass monogram is

backlit and casts a subtle glow. It adds that "little

something extra" to put the composition over the top. You are

sure to score some points on your anniversary with this personal and

unique gift. Finished

and ready for delivery! I think you'll find the results

spectacular. The combination of different woods creates a

wonderful contrast. The texture of the tiger maple is three

dimensional, almost holographic. The stained glass monogram is

backlit and casts a subtle glow. It adds that "little

something extra" to put the composition over the top. You are

sure to score some points on your anniversary with this personal and

unique gift.

Let me know when you want to stop by and pick it up, or you can keep

it hidden at our house if you don't want to risk the wife finding it

before she's supposed to. |

|

|