|

|

Beauty is in the details. Click

on the photos to see them in a larger size. Use your browser's

"Back" button to return. |

|

|

|

January 30, 2015 |

After

the Christmas rush, there just hasn't been a lot of projects running

through the shop. So we figured it was time to do a project

for ourselves. We don't have kids, so there are two spare

bedrooms we use for "personal space." Cindy has a work table

in her room, and I used to practice music in mine. Since I'm

not in a band anymore, that room seemed to lose its primary

function. The short story is that we don't have beds in those

rooms. We recently had a guest stay with us for a week and

could only offer him a futon to sleep on - kind of embarrassing. After

the Christmas rush, there just hasn't been a lot of projects running

through the shop. So we figured it was time to do a project

for ourselves. We don't have kids, so there are two spare

bedrooms we use for "personal space." Cindy has a work table

in her room, and I used to practice music in mine. Since I'm

not in a band anymore, that room seemed to lose its primary

function. The short story is that we don't have beds in those

rooms. We recently had a guest stay with us for a week and

could only offer him a futon to sleep on - kind of embarrassing.

We looked at some contemporary furniture stores around town, but

couldn't find anything that really fit our needs. We wanted a

bed for a small bedroom, a full-size mattress. The bed had to

fit into the corner of the room. There is a window at the

intended location, so the headboard had to stay below the sill.

And there is a floor vent there which we can't cover up. After

a discouraging weekend of shopping, I said to myself, "It's too bad

we don't know someone who could build us one...wait a minute...of

course! Why didn't we think of that?"

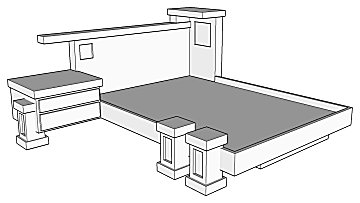

So to the drawing board I went. Here's a SketchUp model of the

design. It fits all the above listed criteria and it will be a

contemporary Prairie school take, which goes with the rest of the

house. I added a built-in side table, too. It will be

made mostly from cherry wood with a few quilted maple accents here

and there. I'll add some integral lighting into the design, as

well, just to add to the coolness factor. I'll post here periodically as construction

progresses, so please check back. |

|

|

|

February 8, 2015 |

I

wanted a closed-in base because it's a lot more stable, and we

really don't need to store anything underneath. Legs can get

rocky after awhile, especially if there's any vigorous activity that

might be taking place. As you can see, it's pretty beefy

construction. A store-bought bed would have just had the

outside box without the extra bracing, but 2x4's are cheap; why not

add them? The outside is black melamine particle board.

It will look like the bed is floating when I get done. I

wanted a closed-in base because it's a lot more stable, and we

really don't need to store anything underneath. Legs can get

rocky after awhile, especially if there's any vigorous activity that

might be taking place. As you can see, it's pretty beefy

construction. A store-bought bed would have just had the

outside box without the extra bracing, but 2x4's are cheap; why not

add them? The outside is black melamine particle board.

It will look like the bed is floating when I get done. |

|

|

|

February 15, 2015 |

The

mattress tray was installed. I left the 3/4" plywood deck off so

you could see the insides. Hey, I don't mess around. This is

how I can give you a lifetime warranty. Any bouncing children

(or other vigorous nocturnal calisthenics) will not damage anything

here. The

mattress tray was installed. I left the 3/4" plywood deck off so

you could see the insides. Hey, I don't mess around. This is

how I can give you a lifetime warranty. Any bouncing children

(or other vigorous nocturnal calisthenics) will not damage anything

here.If you noticed, it is a little off-center. There is a

floor vent near the wall just to the left of the bed that I didn't

want to cover up. If you look at the sketch at the top of the

page, there will be a couple decorative legs which will keep things

stable. The outside is wrapped with figured cherry wood.

You can't see a lot of the figuring now, but when I add the finish,

watch out! It was President's Day Weekend, so we took

advantage of the sales and picked up our mattress. Movin'

right along. |

|

|

|

February 22, 2015 |

I

made the

headboard last week. It's very clean and simple. It's

also lower than you would expect since it has to extend underneath a

window, and I don't want to block the window. I

made the

headboard last week. It's very clean and simple. It's

also lower than you would expect since it has to extend underneath a

window, and I don't want to block the window.

For some visual interest I added a little "window" of quilted maple

framed with wenge wood, "The Window To Dreamland." The top of the headboard will

cantilever off to the left and I'll install a light underneath to

illuminate the side table's top that will be going in below (see the

conceptual sketch at the top of the page). This thing has to

light up just because that adds to the coolness factor.

In the zoomed in shot to the right, notice how the grain wraps

around the corner. You'll only get this attention to detail

with a custom piece. The electric boxes are for the light

switch and a convenience outlet. |

|

|

|

March 2, 2015 |

I

call this side piece the "Tower." I added another little

"window" of quilted maple here and it is illuminated by a small LED

recessed light fixture. This one is the "Portal To Hell." I

call this side piece the "Tower." I added another little

"window" of quilted maple here and it is illuminated by a small LED

recessed light fixture. This one is the "Portal To Hell."

If you click on the first photo, you'll notice that there is some

pretty plastic laminate on the tops which will provide better wear

and the finish looks like glossy black granite. We have this

pattern elsewhere in the house and I was surprised that they still

made it.

One subassembly at a time and I'll be done before you know. |

|

|

|

March 8, 2015 |

These

are the legs! Yes, there are only three of them (see the

conceptual sketch at the top of this page). They feature some

more of those quilted maple "windows." I had clever names for

the other two, so I will call these "Larry, Curly, and Moe." I

still have a lot of little fancy trim work to do on these, but it's a good start. These

are the legs! Yes, there are only three of them (see the

conceptual sketch at the top of this page). They feature some

more of those quilted maple "windows." I had clever names for

the other two, so I will call these "Larry, Curly, and Moe." I

still have a lot of little fancy trim work to do on these, but it's a good start.

In the right photo, you'll see I got going on the side table.

The box is done and the drawers are started. Kinda had to

split my time between the legs and drawer box waiting for the glue

to dry. |

|

|

|

March 15, 2015 |

|

|

|

|

It's starting to look like something now! The side table is

attached and the legs are in place. With custom furniture,

it's about attention to details and details that demand attention.

Check out this leg pairing. One leg would have been enough,

but two make an interesting statement. There are 70 pieces of

wood in this leg pair (yes, I counted). Each one had to be

milled to dimensions and cut to fit nicely with the adjacent pieces.

It is a mix of cherry, wenge and quilted maple woods with faux

granite tops (plastic laminate). You will not see this type of

work in a store bought piece. It simply isn't available

because it takes a lot of the manufacturer's time that they are not

willing to spend. I will spend the time because it entertains

me and this looks way cooler than a square stick of wood on the

corner of the bed. The result is a stunning, one of a kind

ensemble. This is heirloom furniture. |

|

|

|

March 22, 2015 |

I

got all the woodworking done! Now it's time to take the whole

thing apart and apply the finish. My finishing room isn't

quite big enough so I'll have to do this in two gulps. The

overall impression looks a bit like a city skyline, very architectural. Given that I'm an architect, I guess that makes

sense. And it's border collie approved! I

got all the woodworking done! Now it's time to take the whole

thing apart and apply the finish. My finishing room isn't

quite big enough so I'll have to do this in two gulps. The

overall impression looks a bit like a city skyline, very architectural. Given that I'm an architect, I guess that makes

sense. And it's border collie approved!

The attached side table features a faux granite (plastic laminate)

top, full extension, soft-close drawer slides, and stainless steel

hardware. The side table has another one of those fancy legs

on one side and it's attached to the bed frame on the other, so it

appears as if it's floating. Yes, the drawer pulls are offset.

I rarely take the predictable route. The lower pull echoes the

banding on the leg and it draws your eye to the upper shorter pull

and then to the little "window" on the headboard. The pulls

are also easier to reach if you're lying in bed.

Please don't make fun of the console TV. It's a perfect match

for the Atari 2600 sitting on top of it. A retro video game

lover's dream! |

|

|

|

April 11, 2015 |

Since

my spray room was not big enough to fit all the pieces in for one

go, I had to apply the polyurethane in two batches. Each batch

gets 3 coats times 2 sides for a total of 6 applications.

That's 1 coat a day and watch it dry. Thus, it takes about 2

weeks to get all the finish on all the sides. Whew, that's

some math! We threw a small vacation in there, too, but hey,

this piece of furniture is for us, so there's no deadline.

We're in the home stretch now. Just a few more coats to go! Since

my spray room was not big enough to fit all the pieces in for one

go, I had to apply the polyurethane in two batches. Each batch

gets 3 coats times 2 sides for a total of 6 applications.

That's 1 coat a day and watch it dry. Thus, it takes about 2

weeks to get all the finish on all the sides. Whew, that's

some math! We threw a small vacation in there, too, but hey,

this piece of furniture is for us, so there's no deadline.

We're in the home stretch now. Just a few more coats to go! |

|

|

|

April 26, 2015 |

Yes,

done! This bed was custom designed to fit this space. A

commercially available bed could not be found that fulfilled all the

program requirements. It had to be a full-size to fit nicely

in the room, which limits available frame selections. It was

going in a corner, so only one flanking side table. The bed

had to fit under an existing window, hence the lower headboard and a

"Tower" in the corner to anchor the composition. There is a

furnace vent below the window, and the bed's base was offset so the

air could still flow freely. Sorry, you can't really see that

here, but check out some of the construction photos above where it's

more obvious. Yes,

done! This bed was custom designed to fit this space. A

commercially available bed could not be found that fulfilled all the

program requirements. It had to be a full-size to fit nicely

in the room, which limits available frame selections. It was

going in a corner, so only one flanking side table. The bed

had to fit under an existing window, hence the lower headboard and a

"Tower" in the corner to anchor the composition. There is a

furnace vent below the window, and the bed's base was offset so the

air could still flow freely. Sorry, you can't really see that

here, but check out some of the construction photos above where it's

more obvious. |

|

|

|

|

Integral lighting simply makes anything look that much cooler.

The bed was wired up with a convenience outlet and a light switch in

the side of the headboard. The LED puck lights illuminate the

side table and one of the accent panels, which are made from quilted

maple with wenge trim. The lights provide just enough

illumination to cuddle up with a good book (or a Kindle). One note

on LED's. Have you replaced some bulbs in your home with LED's

and they still glow when you turn them off? This is a very

common problem that some folks just decide to live with. That

happened to me on this project, and I was determined not to live

with it. None of the online articles I read provided a clean

and simple solution. Fortunately, being an architect, I

happened to know an especially astute electrical engineer who was up

to the challenge.

The problem is that electronic dimmer switches still allow about 70

volts to pass through them even though the switch is turned off.

That's alright for incandescent bulbs, but LED's are much more

sensitive. One could replace the dimmer with a simple toggle

switch, but that would result in the loss of the dimming

capabilities, unacceptable.

The solution is to bleed off that excess current without

compromising the system's functionality or burning your house down.

With clear direction from my engineer friend, I took some precise

readings with a multi-meter. He worked the numbers through the

appropriate formulas and found that a 100K ohm, 1/2 watt resistor

installed across the hot and neutral wires running to the lights

would bleed off that excess current, and it worked perfectly on the

first try. I'm not saying this will work for every particular

situation, but a clean solution is always possible.

|

I

continually bash a lot of commercial furniture throughout my web

site. I understand that they have to make items which are

"good enough" for the price people are willing to spend for

something. That often means providing lesser quality

materials, less sturdy joinery, and inferior finishes. I also

acquire a lot of business fixing the inevitable damage associated

with those shortcomings. We all know at some point a child

will jump on a bed. Why not just make the bed frame robust

enough to withstand it in the first place? I

continually bash a lot of commercial furniture throughout my web

site. I understand that they have to make items which are

"good enough" for the price people are willing to spend for

something. That often means providing lesser quality

materials, less sturdy joinery, and inferior finishes. I also

acquire a lot of business fixing the inevitable damage associated

with those shortcomings. We all know at some point a child

will jump on a bed. Why not just make the bed frame robust

enough to withstand it in the first place?

My furniture exudes quality. It starts with the solid wood

base constructed as one would your home's floor, with 2x wood at 16"

centers. That is capped with a 3/4" thick plywood deck.

The kids (or particularly frisky adults) may feel free to jump away!

For the exposed surfaces, 3/4" cherry plywood is both sturdy and

beautiful, and it will not warp. For other areas, solid cherry

wood was hand picked by me for the best color and grain. Yes,

I will dig through an entire pile of lumber to find just the right

pieces for a project. The tops of everything are covered with

plastic laminate (many of you have this on your kitchen counters).

It minimizes scratches and water stains and it's available in

thousands of colors and patterns (a glossy granite look here).

You want real granite, not a problem. With custom furniture,

anything is possible.

There is also an abundance of detail to draw one's attention.

The drawers feature full-extension, soft-close, ball bearing drawer

slides that operate very smoothly. The dual legs offer an

interesting focal point at the foot of the bed. The bed was

finished with linseed oil to pop the wood's grain, and polyurethane

to provide the best protection.

|

Yes, custom furniture is more expensive. But I can design any

piece to fulfill even the most stringent of requirements. I

can get it to fit perfectly in a space both dimensionally and

visually. I can match the woods and stains of existing decor.

I will build it right the first time to last a lifetime. Thus,

I have no problem at all offering a LIFETIME WARRANTY (with

no fine print). I am confident and proud to sign and stand

behind anything that goes out the door. |