|

Brian's Guitar from Conception to Birth

or How to Build a Guitar in 62 Easy Steps! |

|

3

Install Alignment Dowels |

The first

thing most people want to do is get directly into cutting out the

shape of the guitar. Resist that urge. Keeping your work surface

square will allow you to transfer measurements from one side of a

panel to the other, it will allow you to use edge routing guides,

and it will provide a broader surface to support your router. Save

the body magic for later.

There are many cavities inside an electric guitar. They all have

different depths and some of them overlap. I thought there should be

an easy way to organize the various routing setups and precisely

control the placement of all the cuts. I came up with a system which

uses dowels to which you can accurately register a multitude of

templates. It allows easy placement of your templates repeatedly in

exactly the same position. You’ll never have an alignment problem

nor a faulty measurement issue when you start carving up your

expensive wood.

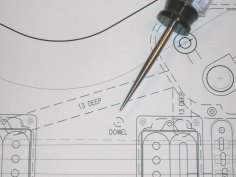

First,

print up a few copies of your guitar body complete with all of your

cavity layouts. Tape it to the body back panel and carefully line up

your center lines. Using an awl, mark the locations of the alignment

dowels. I used four dowels. Remove your pattern and drill holes to

match your dowel diameter. Drill into the body about 12mm. Be

careful not to drill all the way through or you’ll mess up the back

of your guitar. First,

print up a few copies of your guitar body complete with all of your

cavity layouts. Tape it to the body back panel and carefully line up

your center lines. Using an awl, mark the locations of the alignment

dowels. I used four dowels. Remove your pattern and drill holes to

match your dowel diameter. Drill into the body about 12mm. Be

careful not to drill all the way through or you’ll mess up the back

of your guitar.

The

best way to avoid drilling too deep is to set your depth stop on

your drill press. If you don’t own a drill press, you can use

masking tape to mark your drill bit. Just be very careful as masking

tape is not the sturdiest thing and it won’t stop you if you get

heavy-handed. They also make stop collars which attach directly to

drill bits. These will be more forgiving if you push too hard, but

they, too, can still slip. Be very conscious if you’re hand drilling

to keep your drill perfectly level and plumb so you drill straight

down. If you angle your drill, it may make for some alignment

problems later on down the line. The

best way to avoid drilling too deep is to set your depth stop on

your drill press. If you don’t own a drill press, you can use

masking tape to mark your drill bit. Just be very careful as masking

tape is not the sturdiest thing and it won’t stop you if you get

heavy-handed. They also make stop collars which attach directly to

drill bits. These will be more forgiving if you push too hard, but

they, too, can still slip. Be very conscious if you’re hand drilling

to keep your drill perfectly level and plumb so you drill straight

down. If you angle your drill, it may make for some alignment

problems later on down the line.

|

|

|

|

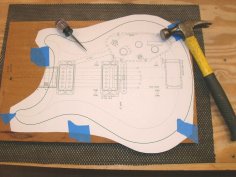

| Now you’ll

need to transfer your dowel locations to the top panel and some 1/4"

thick MDF for some template blanks. Dowel centers are commonly

available and do the trick well. Insert the dowel center into the

holes you just drilled, place your body top panel over them keeping

your center lines aligned (keep your “show-side” out), then gently

push down or rap the top with your fist to leave a slight

indentation. Drill the backside of your top panel about 8mm deep.

Repeat the procedure for the template blanks and transfer your

center lines to these blanks. Now all of these panels can be

repeatedly installed and removed in exactly the same position every

time without measuring, marking, or taping down. |